Gain in-depth insights into How To Make A Stress Strain Curve In Excel, may the information we provide be beneficial for you.

How to Create a Stress-Strain Curve in Excel: A Comprehensive Guide

A Personal Anecdote

Stress-strain curves, a cornerstone of materials science, have long fascinated me. From the intricate patterns they reveal to their profound implications for understanding material behavior, these curves have always sparked my curiosity. In a recent engineering project, I encountered the need to create a stress-strain curve using Microsoft Excel. This experience ignited a desire to share my newfound knowledge and guide others through the process. So, let us embark on a journey to master the art of stress-strain curve creation in Excel.

Unveiling the Stress-Strain Curve: Definition and Significance

A stress-strain curve, also known as a tensile test curve, depicts the relationship between stress and strain within a material. Stress, measured in units of pressure (e.g., Pascal or pounds per square inch), describes the force acting on a given material area. Strain, on the other hand, is a dimensionless quantity representing the deformation of the material relative to its original length. These curves provide invaluable insights into a material’s mechanical properties, such as yield strength, ultimate tensile strength, and Young’s modulus.

Preparing Your Data: Gathering and Formatting

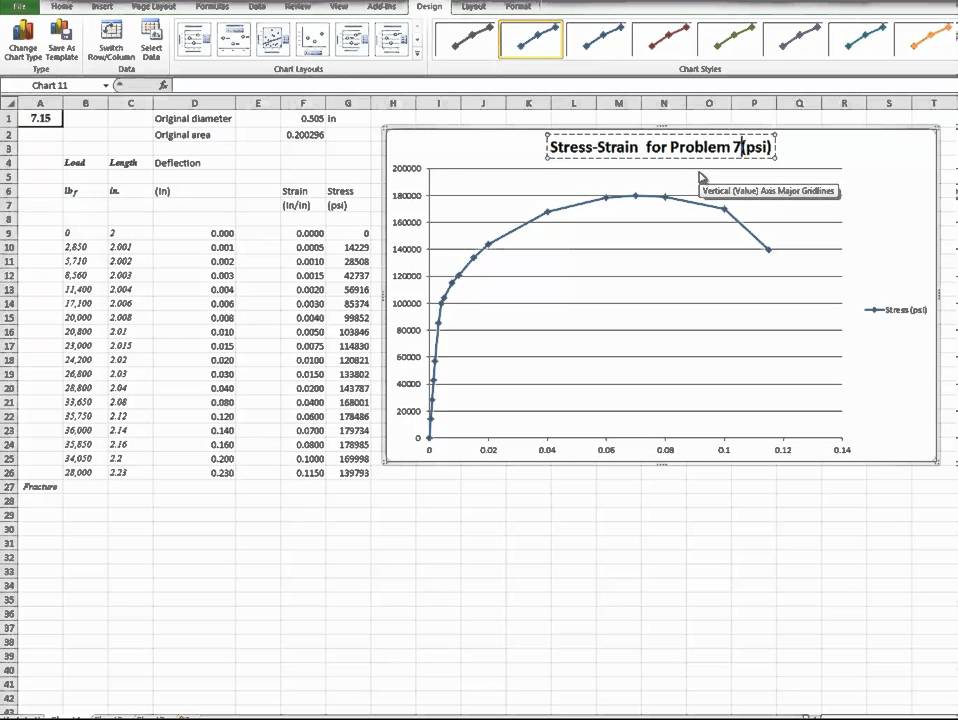

To create a stress-strain curve in Excel, you will need two columns of data: stress and strain. Stress values are typically measured using a load cell, while strain can be obtained using an extensometer or by measuring the elongation of the specimen under load. Once you have collected your data, enter it into two adjacent columns in Excel. Ensure that the values are correctly aligned and that there are no missing or erroneous data points.

Crafting the Curve: Charting and Customization

Once your data is prepared, you can create the stress-strain curve by selecting both columns and clicking on the ‘Insert’ tab in the Excel ribbon. Choose the ‘Scatter’ chart type and select the ‘Smooth Lines’ option to generate a curve. The resulting chart will display the stress on the y-axis and the strain on the x-axis.

To customize the chart, you can adjust the axis labels, add a title, and change the color and thickness of the line. Additionally, you can add gridlines to enhance readability and better visualize the relationship between stress and strain.

Interpreting the Curve: Unveiling Material Behavior

A stress-strain curve typically consists of several distinct regions, each revealing a different aspect of the material’s behavior. The initial linear region represents the elastic deformation of the material, where it responds linearly to applied stress. As stress increases, the material enters the plastic deformation region, where it undergoes permanent deformation. The yield point marks the transition between elastic and plastic deformation, and the ultimate tensile strength indicates the maximum stress the material can withstand before breaking.

Latest Trends and Developments: Unlocking Enhanced Analysis

In recent years, advancements in material testing techniques have led to the introduction of more sophisticated stress-strain curve analysis methods. These methods employ computational techniques to extract detailed mechanical properties from stress-strain curves. For example, the n-exponent method allows for the quantification of material hardening behavior, while advanced curve fitting algorithms can identify specific material models.

Tips and Expert Advice: Enhancing Accuracy and Interpretation

- Ensure Data Integrity: Verify the accuracy of your data before creating the curve. Any inaccuracies can significantly impact the interpretation of the results.

- Consider Material Properties: Different materials exhibit unique stress-strain behaviors. Be aware of the material’s properties to better understand the curve’s implications.

- Interpret the Curve Contextually: Stress-strain curves should be interpreted in the context of the material’s intended application. Consider factors such as loading conditions, environmental effects, and potential failure modes.

Frequently Asked Questions: Clarifying Common Queries

Q: Why is it important to create stress-strain curves?

A: Stress-strain curves provide valuable insights into a material’s mechanical properties, allowing engineers to design and optimize components for specific applications.

Q: What factors affect the shape of a stress-strain curve?

A: Factors such as material composition, temperature, loading rate, and heat treatment can influence the shape of a stress-strain curve.

Q: How can I determine the yield strength from a stress-strain curve?

A: The yield strength is typically identified as the point where the stress-strain curve deviates from linearity in the elastic deformation region.

Conclusion

Creating a stress-strain curve in Excel is a valuable technique for understanding the mechanical properties of materials. By following the steps outlined in this guide, you can confidently generate and analyze these curves, unlocking a deeper understanding of material behavior. Whether you are a seasoned engineer or a student eager to explore the world of materials science, the ability to create and interpret stress-strain curves will empower you with actionable insights.

Are you interested in learning more about stress-strain curves and their applications?

Image: mavink.com

An article about How To Make A Stress Strain Curve In Excel has been read by you. Thank you for visiting our website, and we hope this article is beneficial.